With the roof40, you obtain a high welding performance at an affordable price. The overlap welding machine is ideal for all thermoplastic membranes like PP, PVC, TPO, ECB, modified EPDM, EVA, FPO, PIB, PMI, and PO. The digital display of roof40 ensures easy handling.

1. Ideal for overlap welding for base seams

2. Edge close welding on up to 100 mm

3. 40 mm welding width

4. Freely-selectable speed up to 10 meter per minute

5. High-performance 3450 W hot-air gun for the desired temperature and air volume

6. Automatic start-up system for optimal welding start

7. Guide bar and handle for ergonomic use

8. Digital display for speed, temperature and air volume

| Parameters | Weldy Roof40 |

| Voltage | 230V, 50/60Hz |

| Power | 3450W |

| Welding Speed | 1 - 10.0 M/MIN |

| Heating temperature | 100 - 600 ºC ADJUSTABLE |

| Welding Width | 40 MM |

| Power Cable Length | 3 M/MIN |

| Air Volume | 60 - 100 % |

| Machine Dimension | 475 x 244 x 260 MM |

| Machine Weight | 15.5 kg |

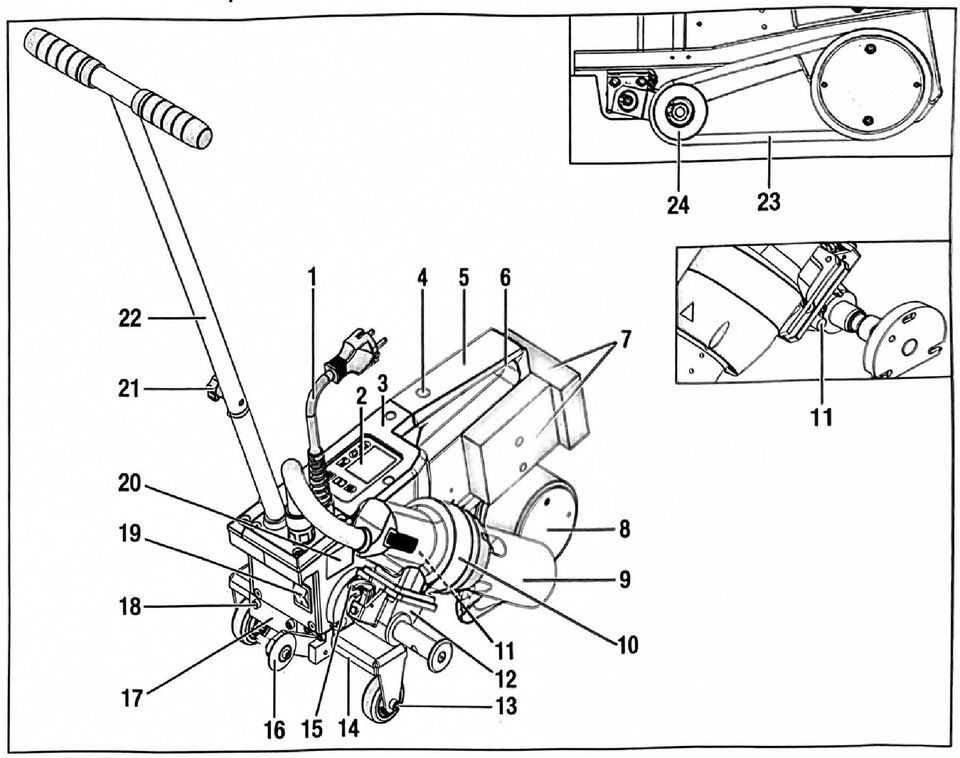

1. Power cord

2. Operating unit

3. Housing

4. Opening for fastening any holding/carrying hand-les and device fastening equipment

5. Carrying handle

6. Holder for power cord (with carabiner for hooking up)

7. Additional weights at the rear/on the side

8. Drive/pressure roller (patent pending)

9. 40mm welding nozzle

10. Hot-air blower

11. Starting switch

12. Swivel-in mechanics

13. Transport roller

14. Movable transport axle (patent pending)

15. Hot-air blower lock

16. Track guide roller

17. Clamping plate for movable transport axle

18. Hexagon socket screws for detaching the movable transport axle

19. Main switch (switching On/Off)

20. Type plate with model designation and the series marking

21.L ocking screw (guide bar)

22. Guide bar,top

23. Downholder belt

24. Deflection roller

Highlights Versatile and easy

1 comments