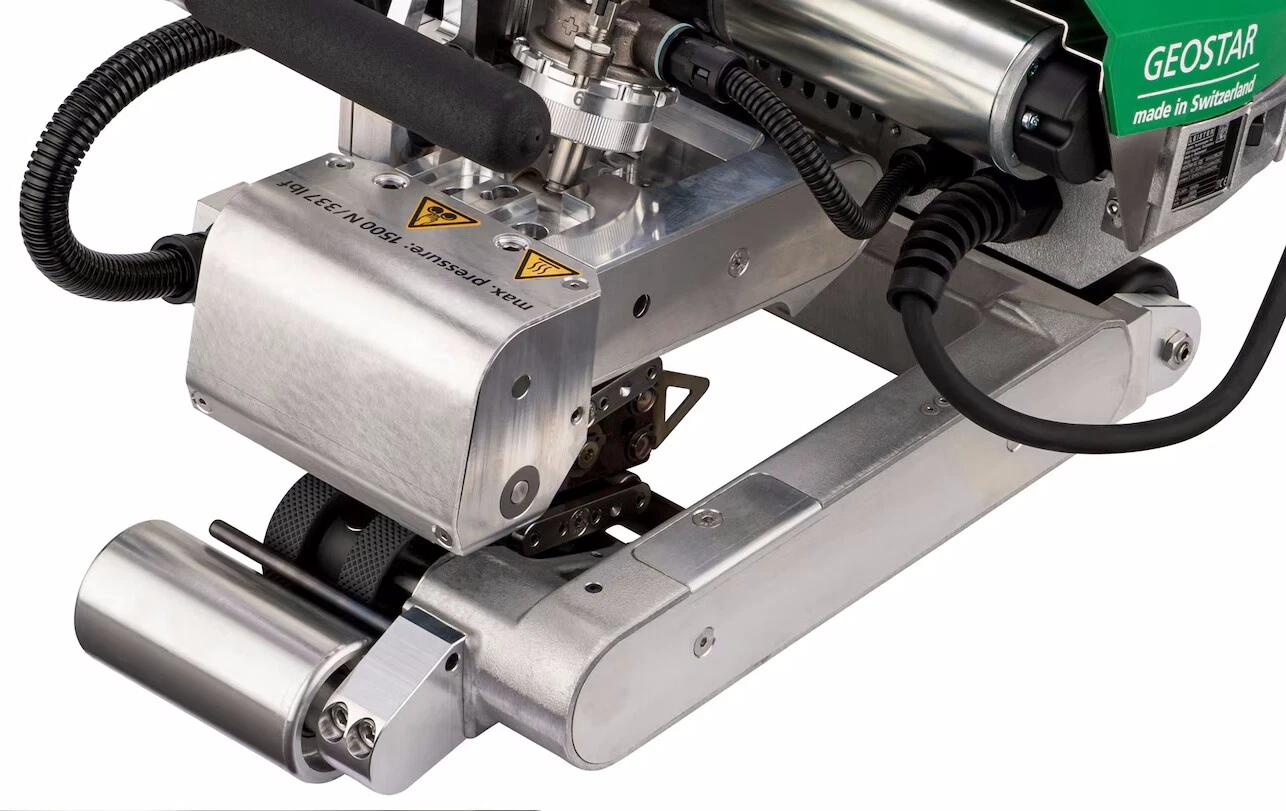

The GEOSTAR G5 LQS is an automatic welder used to weld geomembranes with the Leister Quality System (LQS). The LQS function allows data identification and monitoring of all welding parameters: i.e. speed, temperature and pressure. Thanks to built-in Wifi, wireless data transmission is easy and convenient. Via the LQS app, quality documentation, tables, and graphics are easy to create and, in addition, pdf and csv exports can be created

The maintenance-friendly automatic welder weighs less than 17 kg and is therefore lighter than the GEOSTAR G7. The sophisticated aluminum construction allows for optimal maintenance positions with easy access to the mechanical parts of the machine (both for cleaning components and converting). Furthermore, GEOSTAR G5 LQS is easy to use and the hot wedge can be replaced in less than one minute. The GEOSTAR G5 LQS easily and safely welds various geomembranes made of HD-PE, PP, LD-PE, TPO, FPO, PVC-P, CSPE and EIA with a material thickness ranging from 0.8 to 3 mm (30 to 120 mil).

Technical Data

Article: 156.135

Voltage: 230 V

Frequency: 50/60 Hz

Power: 2800 W

Temperature: 80 - 460 °C / 176 - 860 °F

Speed: 0.8 - 12 m/min / 2.62 - 39.37 ft/min

Welding Technology: Hot Wedge

Hot Wedge Length: 90 mm / 3.54 in

Hot Wedge Width: 50 mm / 1.96 in

Hot Wedge Material: Copper

Max. Overlap: 150 mm / 5.9 in

Max. Welding Pressure: 1500 N / 337.21 lbf

Weld Seam Width: 2 x 15 mm / 2 x 0.59 in

Roll Material: Steel Roller Sharp Diagonal

LQS: Yes

Display: Yes

Length: 482 mm / 18.97 in

Width: 278 mm / 10.94 in

Height: 269 mm / 10.59 in

Weight: 16.8 kg / 37.03 lb

Welding Materials: FPO; HDPE; LDPE; LLDPE; PE; PP; TPO

Weldable Material Thicknesses: 0.8 - 3 mm / 31.49 - 118.11 mil

Power Cable Length: 3 m / 9.84 ft

Plug: EU, 3 poles, 16A

Approvals: CB Certification; CE; UKCA

Protection Class: I

Country Of Origin: Switzerland

Features:

- 90 mm (3.5 in) hot-wedge for PE

- Recorded welding parameters

- GPS function shows welding location details

- Ergonomic, single-hand operation

- Including storage box

HIGHLIGHTS Digital operation

Parameters controlled via digital display

The pressure, welding speed and temperature are monitored and controlled via the digital display.

Optimized clamp

The practical clamping mechanism simplifies single-hand operation by integrated clamping and handle-locking.

Glides over membranes with ease

Smooth operation, thanks to the optimized wedge shape. Changing the wedge is possible in less than one minute.

APPLICATIONS Virtually unlimited

Foundation waterproofing

Landfill and mining membrane welding

Pond waterproofing

Reservoirs and canals waterproofing