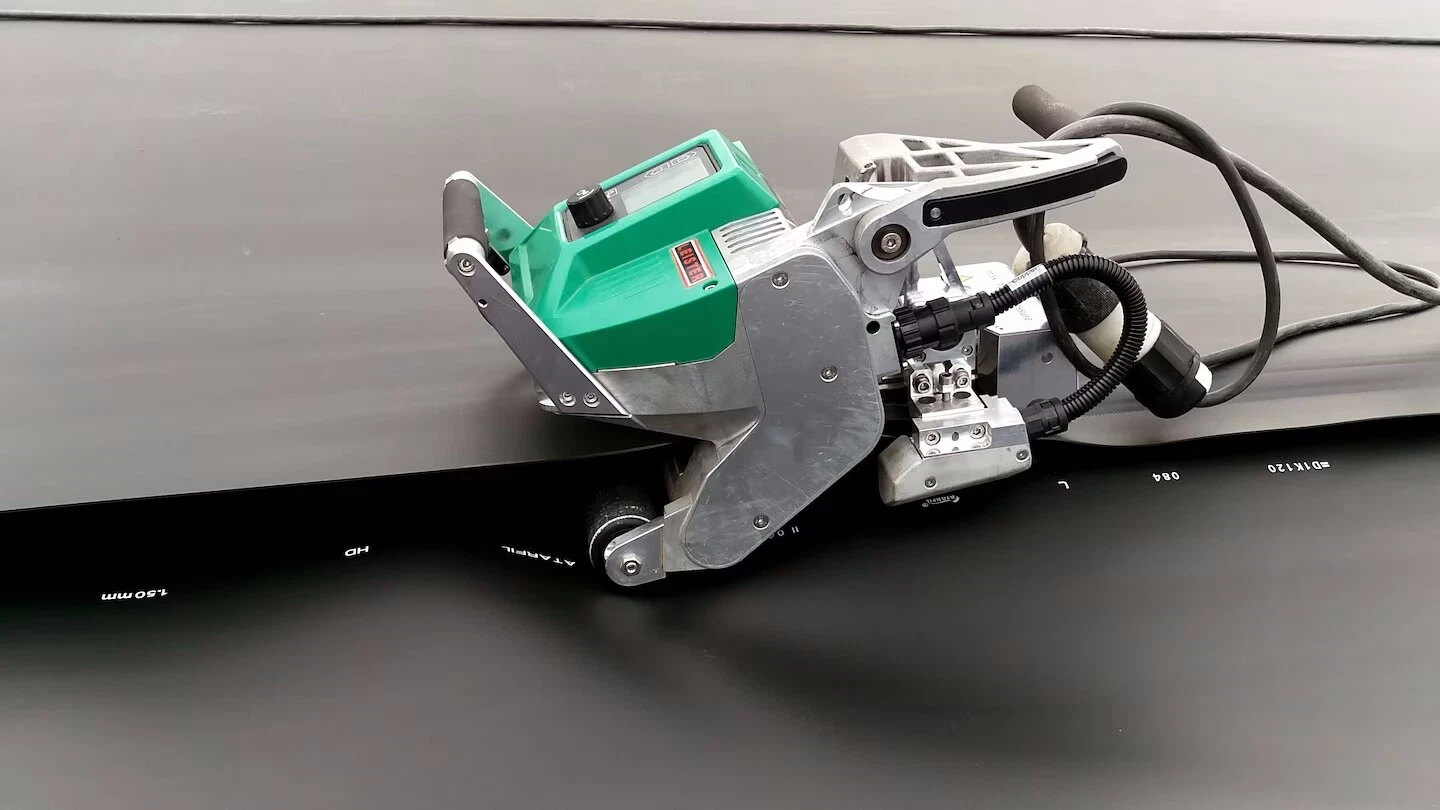

The GEOSTAR G7 is a maintenance-friendly, easy-to-use hot-wedge welding machine. It is optimized for civil engineering, landfills and mines. The sophisticated frame made of solid cast aluminum is advantageous. Furthermore, the integrated clamping and handle locking mechanism guarantees simple, single-hand operation. At welding speeds up to 12 m/min (39ft/min), the GEOSTAR G7 welds geomembranes that cover large areas.

An additional advantage is that the hot wedge can be replaced in less than one minute, thanks to the new wedge connection. Geomembranes made of HD-PE, PP LD-PE, TPO and FPO with a material thickness between 1 mm and 3 mm (40 and 120 mil) are easily welded with the GEOSTAR G7. Leister will check additional materials for their weldability on request. The key difference between the GEOSTAR G5 and the GEOSTAR G7 is the wedge length. Thanks to the 130 mm long wedge, noticeably higher performance is possible with the GEOSTAR G7.

Technical Data

Article: 151.035 / 156.310

Voltage: 230 V

Frequency: 50/60 Hz

Power: 2800 W

Temperature: 80 - 460 °C / 176 - 860 °F

Speed: 0.8 - 12 m/min / 2.62 - 39.37 ft/min

Welding Technology: Hot Wedge

Hot Wedge Length: 130 mm / 5.11 in

Hot Wedge Width: 50 mm / 1.96 in

Hot Wedge Material: Copper

Max. Overlap: 150 mm / 5.9 in

Max. Welding Pressure: 1500 N / 337.21 lbf

Weld Seam Width: 2 x 15 mm / 2 x 0.59 in

Roll Material: Steel Roller Sharp Diagonal

LQS: No

Display: Yes

Length: 482 mm / 18.97 in

Width: 278 mm / 10.94 in

Height: 269 mm / 10.59 in

Weight: 18.1 kg / 39.9 lb

Welding Materials: FPO; HDPE; LDPE; LLDPE; PE; PP; TPO

Weldable Material Thicknesses: 1 - 3 mm / 39.37 - 118.11 mil

Power Cable Length: 3 m / 9.84 ft

Plug: EU, 3 poles, 16A (151.035) / UK, 3 poles, 13A (156.310)

Approvals: CB Certification; CE; UKCA

Protection Class: I

Country Of Origin: Switzerland

Features:

- 130 mm (5.1 in) heating wedge for faster welding

- Higher performance than GEOSTAR G5

- Hot-wedge welding machine with a strong drive motor

- Hot wedge replacement in less than one minute

- Display of the welding parameters and voltage

HIGHLIGHTS Underground engineering redefined:

STRONG

Closed-loop high-performance drive motor

The drive motor of the GEOSTAR G7 has 100% more power than that of the GEOSTAR G5.

FASTER

Large hot wedge

The large hot wedge enables welding speeds up to 45% faster than the GEOSTAR G5

A LOT OF SPACE

Feed material with ease

GEOSTAR G7s optimized, lightweight frame allows geomembranes to be easily inserted at the start of the welding process, making it faster for the user to start welding.

APPLICATIONS Virtually unlimited

Foundation waterproofing

Landfill and mining membrane welding

Pond waterproofing

Reservoirs and canals waterproofing