3 years warranty ! lifetime long technical support & free parts replacement !

Product details:

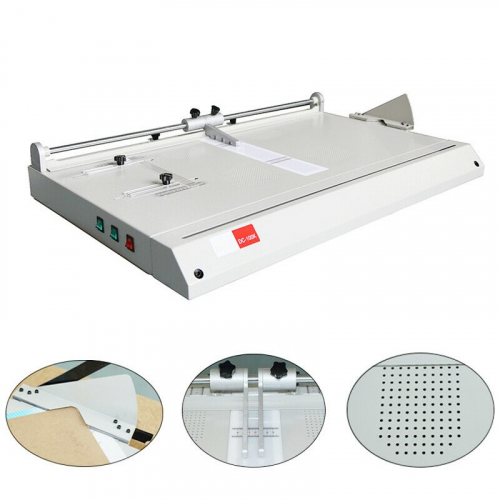

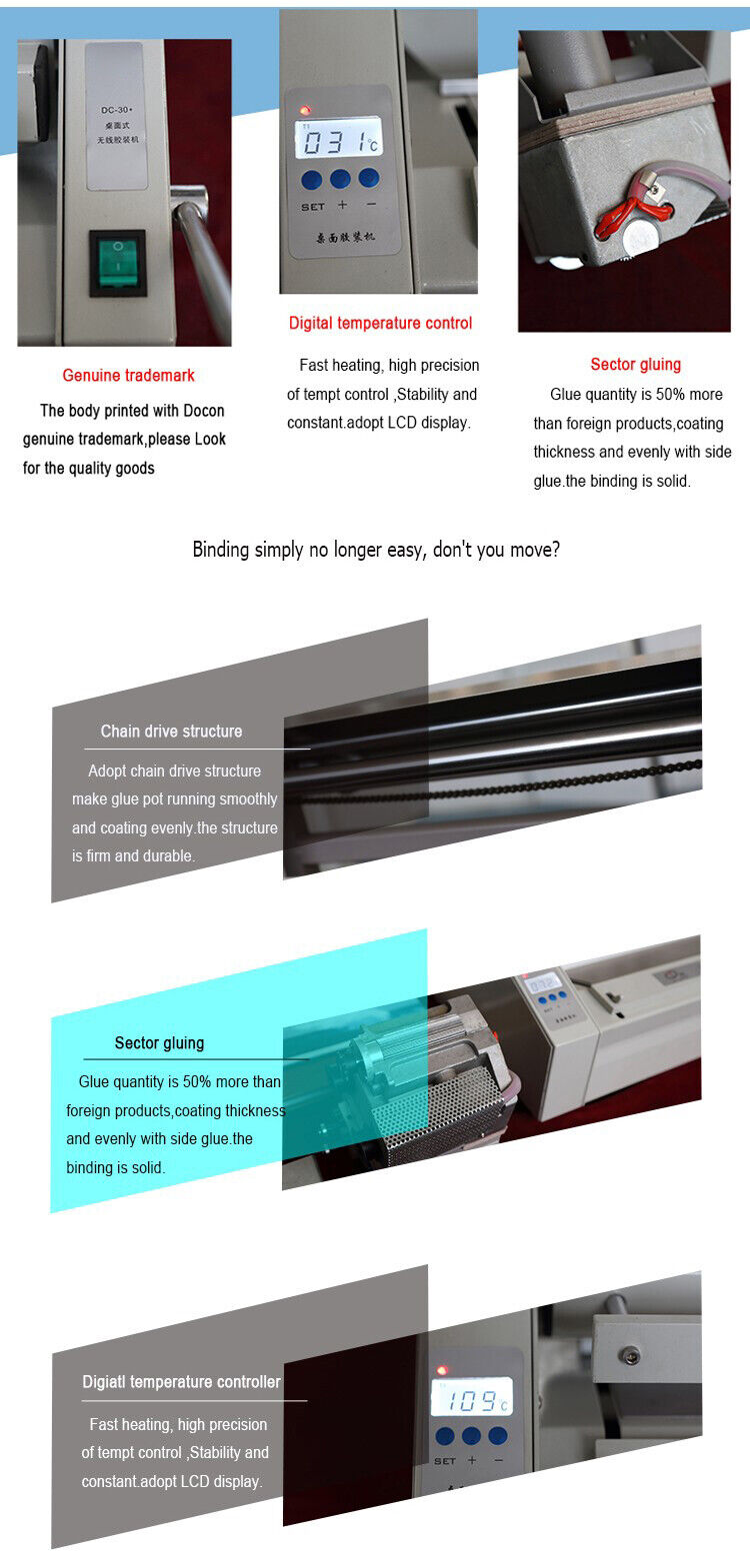

Model: DC-30+

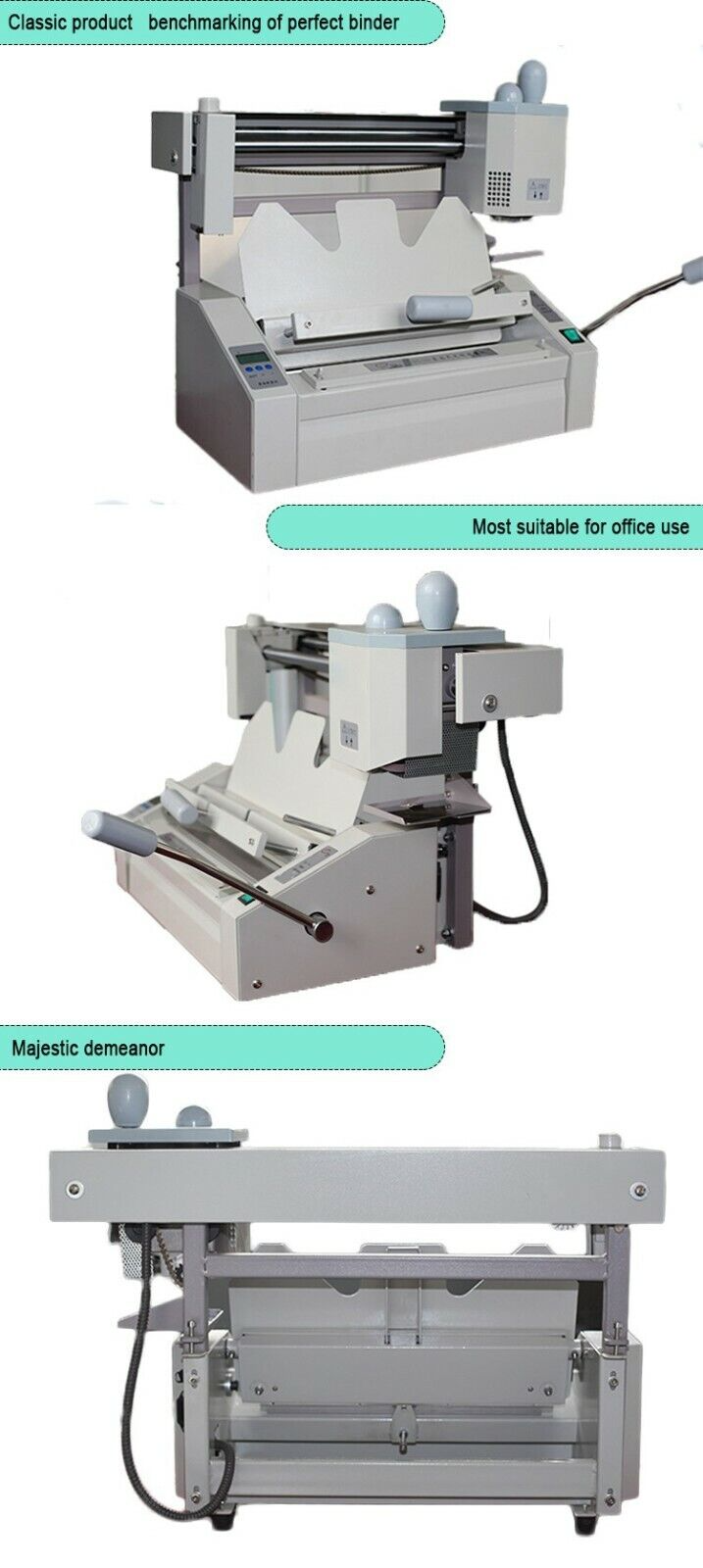

Type: desktop perrfect binding machine.

Speed: 180 books/hour

Display mode: LCD display

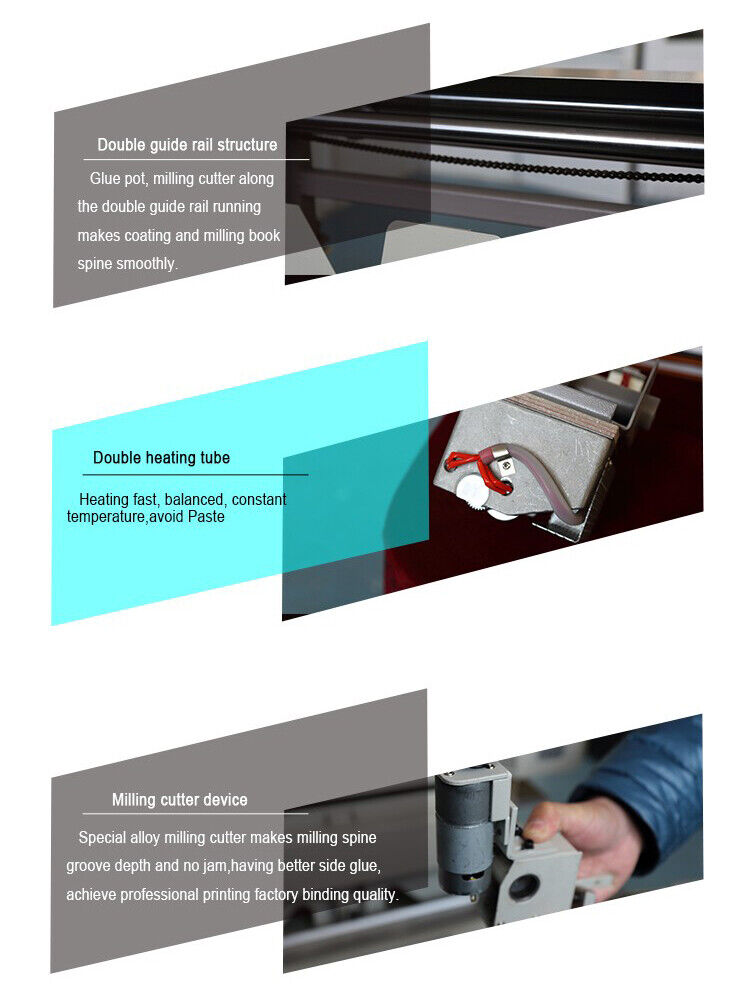

Digital temperature control: Yes

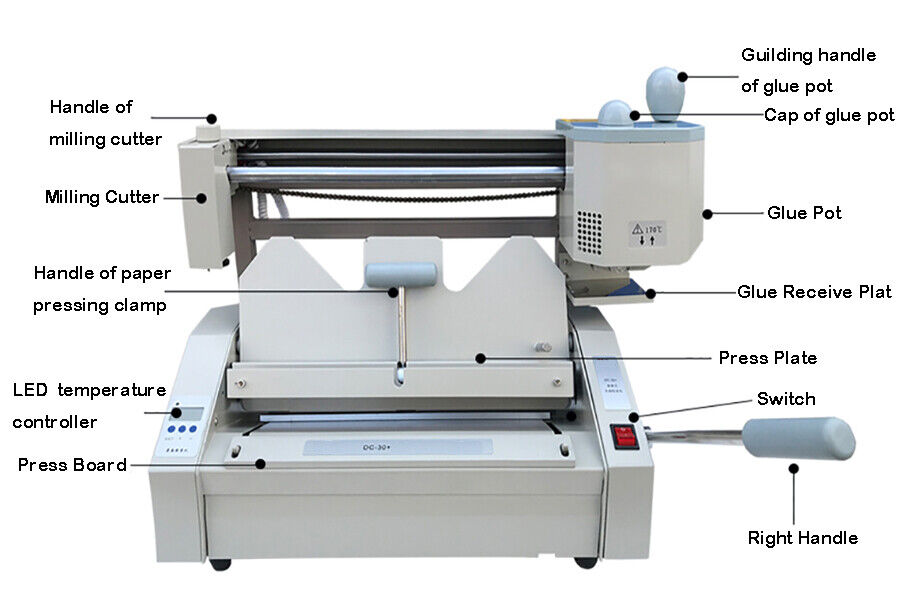

Milling cutter:yes

Preheating time: 10 mins

Max binding size: 320x 280mm (12.6''x 11'')

Max binding thickness: two pages-40mm

Max cover thickness:50-400g

Heating time: 15min (depends on ambient temperature)

Power: 500W

Dimension: 650x350x500mm

Machine net weight: 36kg

1. 1 x Binding machine

2. 1 x Power cord

3. 1 x Adhesive can cap

4. 1 x Gliding handle of the adhesive can

5. 1 x Service manual

6. 1 x Adhesive bag

8. 2 x Fuse

9. 2 x Inner hexagon spanner

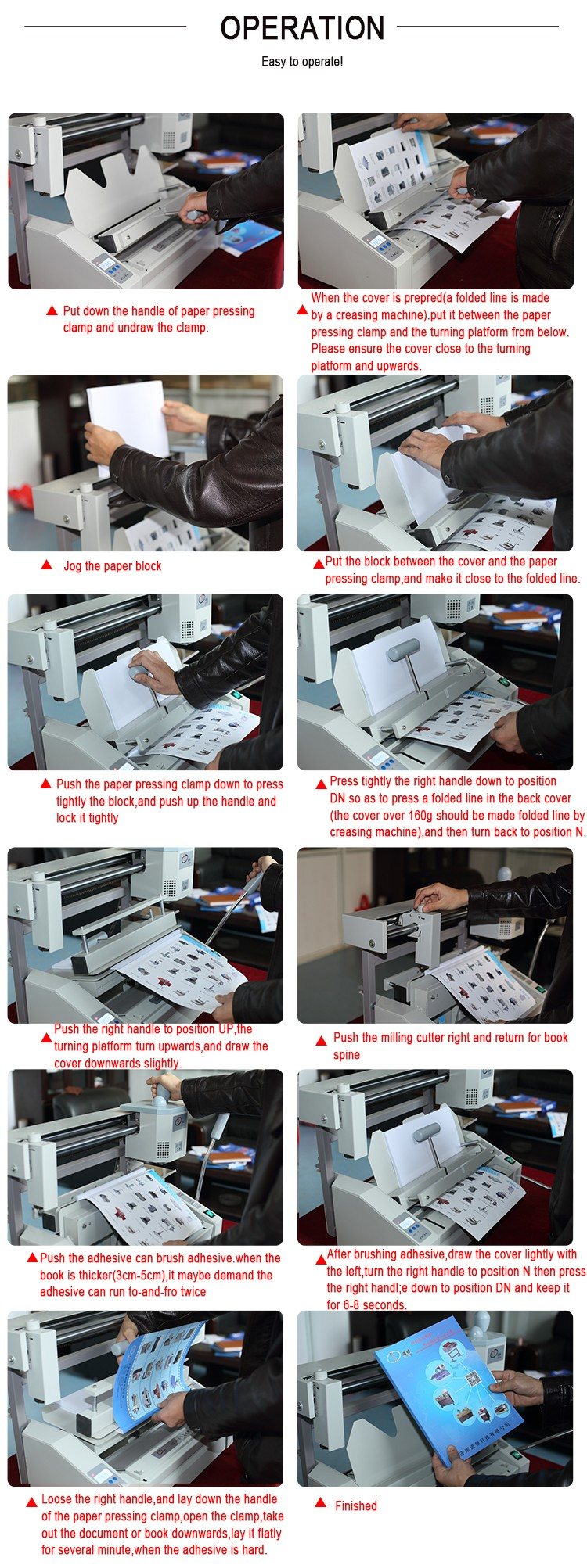

Operating Instructions

1. Temperature-controlling instrument: the temperature is arranged at 338 ℉ at the time of exfactory (using the hot melt glue provided by our company); If hot melt glue of other style is adopted, the temperature can be adjusted according to its melting point. 2. Operations of milling cutter: push the cutter to-and-fro, when the book spine is well milled, brush the adhesive. 3. Hardcover hot groove-pressing device put the hard cover in the paper pressing clamp tightly and press the right handle down to tighten the hard cover for 5-10 seconds. Attention: there is electricity-powered constant temperature device (50℃) on the hardcover hot groove-pressing board; therefore, it should be avoided from destruction or touched by hands. The small switch at the right side can control whether the hardcover hot groove-pressing board is connected with electricity, so that the user can choose hot-pressing or cold-pressing.

Installation:

Please lay the machine on a steady working platform, avoiding wet

place. Proper space around should be ensured for convenient operation

The can cap, and the gliding handle should be installed.

Preparations before installation:

1. Please connect to suitable power, and check the amount of the left

adhesive. Adhesive granule should be added in time. The heights of

the adhesive not overrun the pointer inside the adhesive can.

2. After connect the power, turn on the switch. And the adhesive can is

heated. The hot-melt time is 15-20 min.

place. Proper space around should be ensured for convenient operation

The can cap, and the gliding handle should be installed.

Preparations before installation:

1. Please connect to suitable power, and check the amount of the left

adhesive. Adhesive granule should be added in time. The heights of

the adhesive not overrun the pointer inside the adhesive can.

2. After connect the power, turn on the switch. And the adhesive can is

heated. The hot-melt time is 15-20 min.

CAUTION (1):

Do not push the adhesive can when it is cold or the

hot-melt time is not sufficient, or else it can be

damaged

Keep the surroundings of the machine clean

avoiding the impurity getting into the adhesive can and

causing damage

Avoid touching the adhesive roller with the hard

material which can damage it.

Please turn off the switch and cut off the power when

the machine is not used.

3. Please check whether the cover pressing board suits the cover of the

documents to be made.

4. Put the right handle at position N

hot-melt time is not sufficient, or else it can be

damaged

Keep the surroundings of the machine clean

avoiding the impurity getting into the adhesive can and

causing damage

Avoid touching the adhesive roller with the hard

material which can damage it.

Please turn off the switch and cut off the power when

the machine is not used.

3. Please check whether the cover pressing board suits the cover of the

documents to be made.

4. Put the right handle at position N

CAUTION (2):

1. Please ensure no impurity get into the adhesive can, such as waste

paper, wood dust, steel pin, etc, or the can can be jammed.

2. The folding line should be well folded to ensure the rectangular

shape of the spine. To buy a creasing machine is recommended.

3. The quantity of added adhesive should not overrun the position

pointed by the arrow in the can, or the adhesive will overflow.

paper, wood dust, steel pin, etc, or the can can be jammed.

2. The folding line should be well folded to ensure the rectangular

shape of the spine. To buy a creasing machine is recommended.

3. The quantity of added adhesive should not overrun the position

pointed by the arrow in the can, or the adhesive will overflow.