UNIPLAN 500

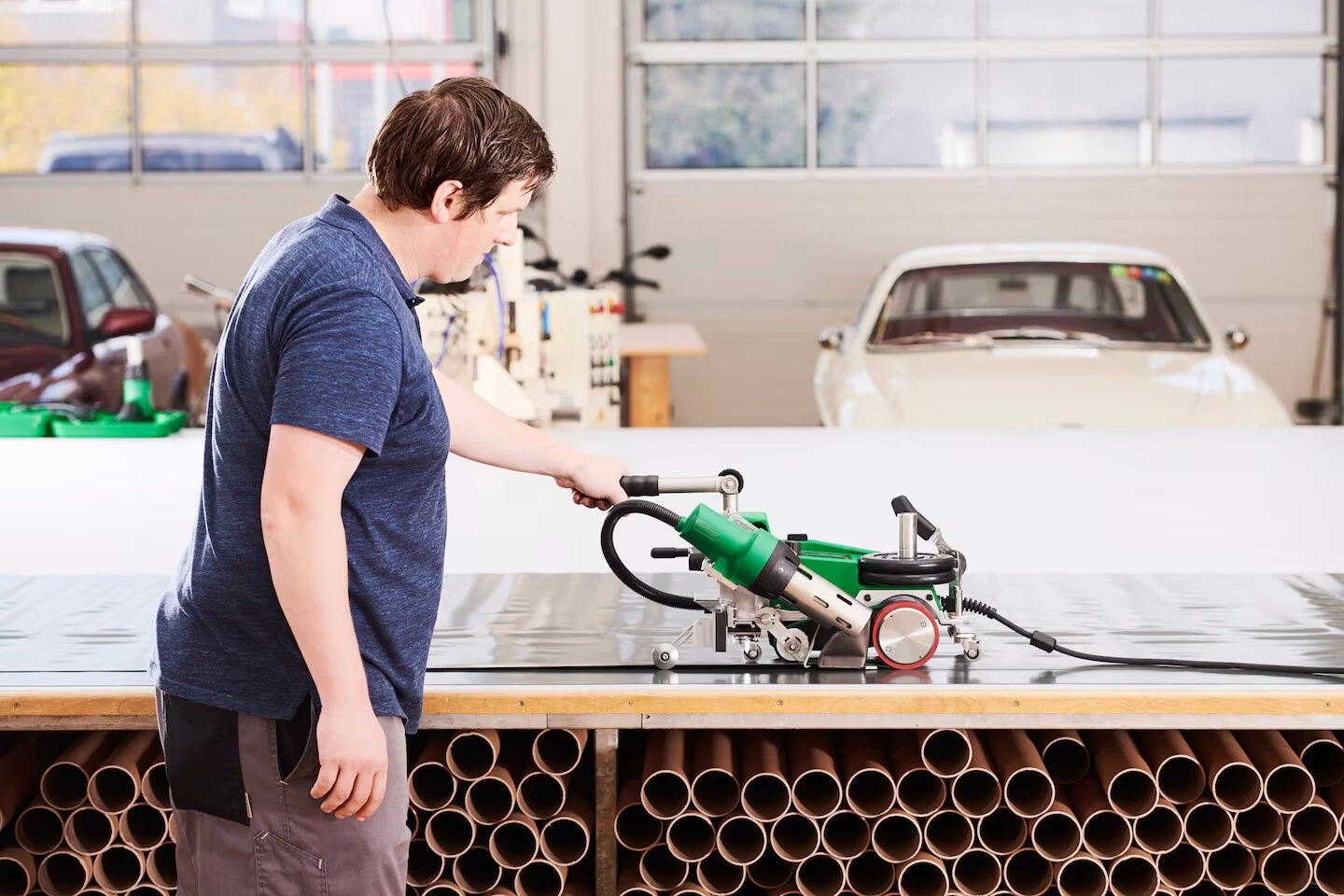

The UNIPLAN 500 automatic welder has a low-maintenance, brushless motor, a hot air blower with 18,000 rpm for high welding power and is perfectly suited for overlap, hem and piping on various industrial fabrics. The device is easy to use on the table, as well as on the floor. The integrated lifting device makes it easier to prepare and feed the material before welding.

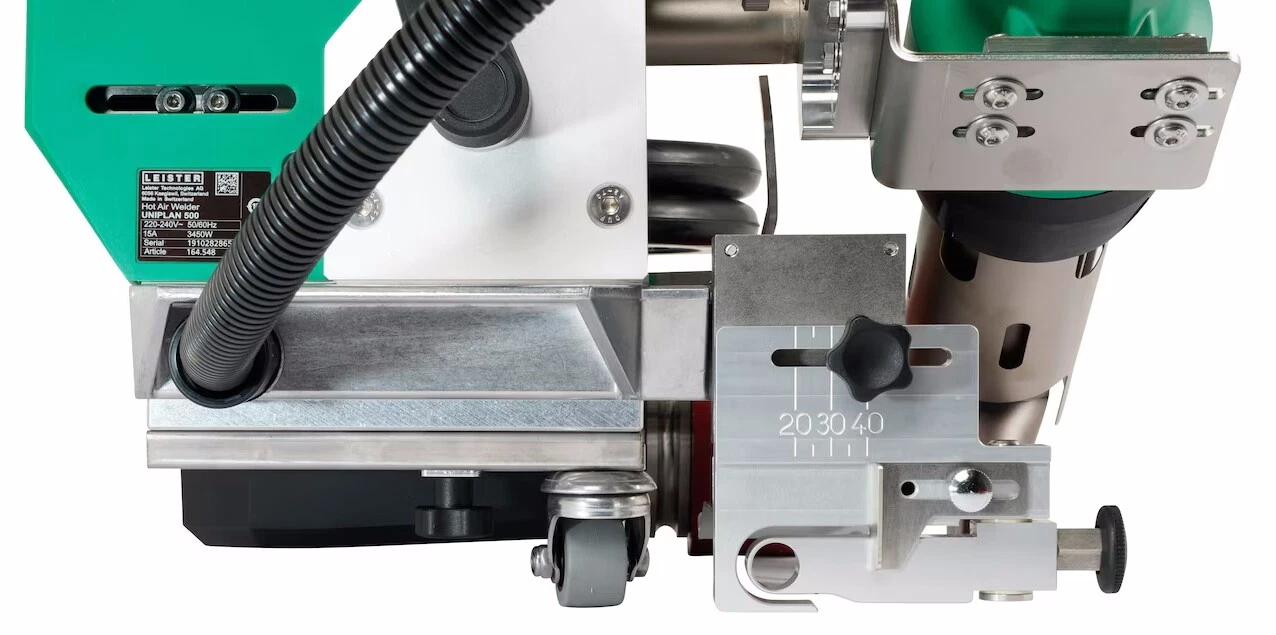

Automatic single motion nozzle engagement offers increased process safety. An advantage is the manually, adjustable swivel wheel on the UNIPLAN 500, which prevents annoying snagging on lugs, rivets, and tensioning hooks when welding. Another advantage of the UNIPLAN 500 is the simple operation via display with e-drive. The drive and temperature are controlled and the parameters can be stored. It is easy to switch between overlap welding and hem or pipe welding. Various accessories are included with the UNIPLAN 500: In addition to a transport box and overlap guide, extra weights (1.25 kg or 2.76 lb each), including weight holder, a brass brush, a short handle with console, a nozzle adjustment gauge and an additional hem guide are included.Technical Data

Article | Voltage | Power | Welding Nozzle / Seam Width | Plug |

164.556 | 230 V | 3450 W | 20 mm / 0.78 in | CEE blue, 3 poles, 16A |

164.555 | 230 V | 3450 W | 30 mm / 1.18 in | CEE blue, 3 poles, 16A |

146.554 | 230 V | 3450 W | 40 mm / 1.57 in | CEE blue, 3 poles, 16A |

Frequency: 50/60 Hz

Speed: 1 - 16 m/min / 3.28 - 52.49 ft/min

Temperature: 100 - 620 °C / 212 - 1148 °F

Air Volume Adjustable: Yes

LQS: No

Brushless Blower Motor: Yes

Length: 500 mm / 19.68 in

Width: 310 mm / 12.2 in

Height: 300 mm / 11.81 in

Weight: 16 kg / 35.27 lb

Power Cable Length: 3 m / 9.84 ft

Approvals: CB Certification; CE; UKCA

Protection Class: I

Country Of Origin: Switzerland

Features:

-Powerful hot-air blower with 18,000 rpm

-Brushless blower motor

-Single motion nozzle engagement

-Automatic material lifting device

-Adjustable swivel wheel to avoid obstacles

HIGHLIGHTS Welding on tables or floor

1. INCREASED PROCESS SAFETY

Automatic single motion nozzle engagement simplifies work.

2. A HIGHLY PRACTICAL SOLUTION Integrated material lifting device

Simplifies and automates welding

3. QUICK GUIDE REPLACEMENT Adjusted in single operation

Easy to switch from overlap to hem guide or pipe guide

APPLICATIONS Virtually unlimited

Tent tarpaulin welding

Advertising banner welding

Protective cover welding

Plastic fabric hoses welding

Textile roofing and facade welding

Inflatable plastic fabrics welding

Awning and wind blocker welding

Truck tarpaulin welding

Pool waterproofing