product description

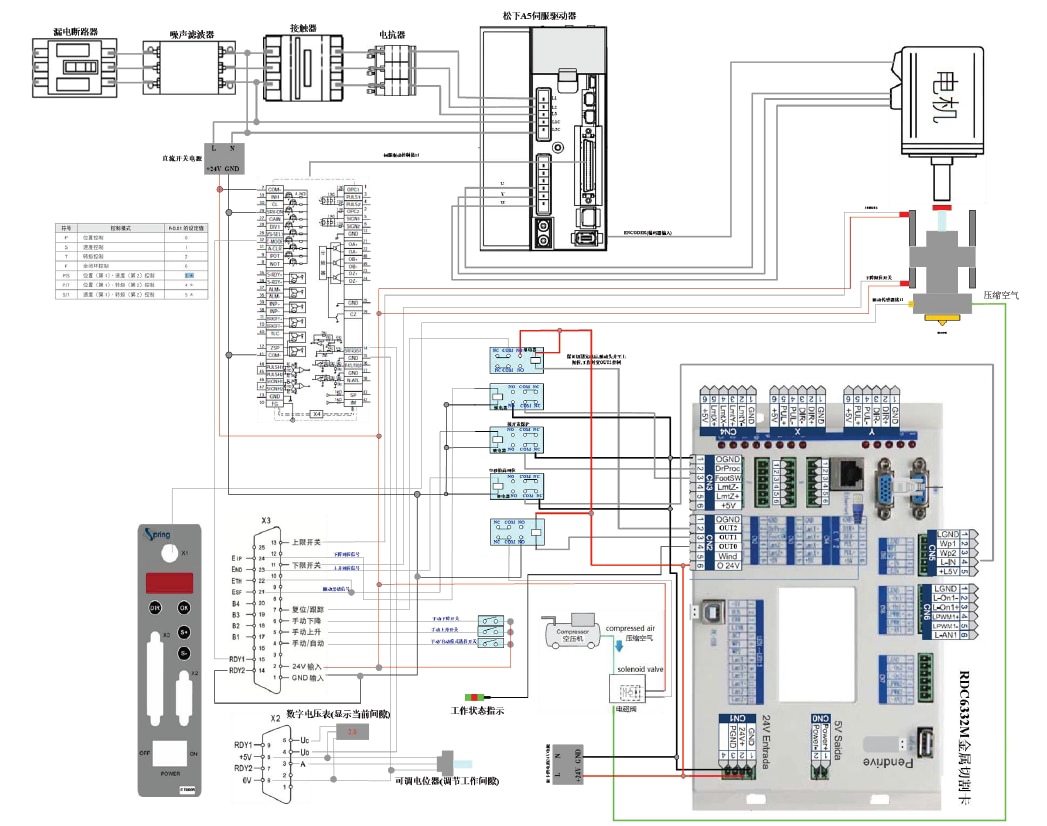

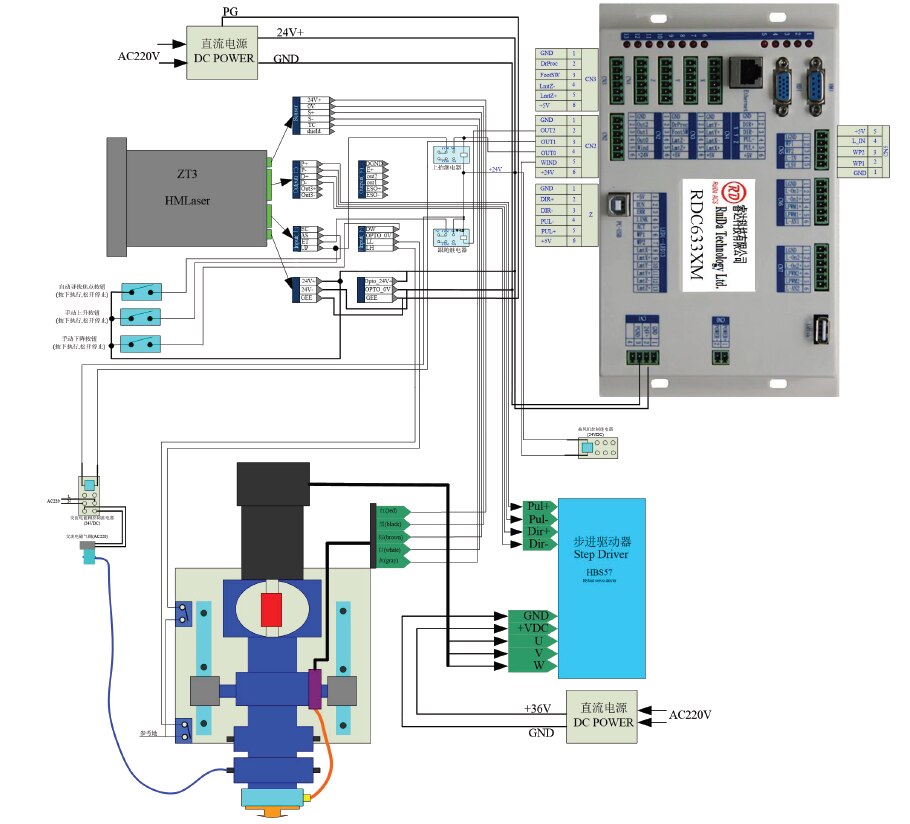

Non-metal automatic height adjustment laser control system, integrated non-metal automatic height adjustment device, can complete the automatic height adjustment processing of uneven or non-metal working surface. Supports auxiliary gas control.

Technical Parameters:

1. Two digital laser control signals

(1) Differential output, TTL level, 20mA drive capability;

(2) The PWM frequency is adjustable from 2.5K to 100K;

(3) The PWM duty cycle is adjustable from 2% to 98%;

2. Two analog laser control signals 0 ~ 5V automatically follow and adjust;

3. Differential output of motor control signal, TTL level, 20mA drive capability;

4. The maximum motor control pulse frequency is 500KHZ;

5. The maximum USB transmission rate is 12M, and the longest distance is 5 meters;

6. Linear / circular / B-spline interpolation accuracy +/- 0.5 pulse;

7. 4-channel general photoelectric isolation OC gate output, maximum 300mA drive capability, can directly drive the relay;

Function description:

1. Ethernet (10 / 100M) and USB2.0 transmission;

2. 3.5-inch true-color TFT screen, which can display true-color processing graphics on the panel, and at the same time can accurately know the coordinate position of the laser head processing on the panel;

3. The file graphics saved in the memory can be previewed on the panel, and the screen speed is fast;

4. Can dynamically display the track processing progress and coordinate points;

5. The processing parameters (such as speed, power, etc.) of each layer can be directly modified on the operation panel, and the modified layer parameters can be automatically saved for future use;

6. Support power-off and engraving, working time preview (accurate to the millisecond level, the working time preview value is exactly the same as the actual work time);

7. Support functions such as feeding, lifting, rotary engraving, and left and right push plates;

8. The system has better hardware stability and better anti-high voltage and anti-static interference characteristics;

9. The controller uses a more complete and optimized motion control algorithm, which has higher processing speed and efficiency;

10. Onboard real-time clock;

11. Expansion port is reserved, which can be connected with Ruida wireless controller device for wireless control;

12. Cooperate with Ruida's non-metallic height-adjusting system, and apply to the non-metallic cutting field where the laser head follows the movement;